Parametric Method Helps NASA Make Early Cost Estimates of Pluto Mission

Pluto is the only planet in our Solar System not yet viewed close-up by spacecraft, and given its great distance and tiny size, study of the planet continues to challenge and extend the skills of planetary astronomers. Most of what we know about Pluto we have learned since the late 1970s. Many of the key questions about Pluto and its satellite Charon await the close-up observation of a space flight mission. Beyond Pluto lies the recently-discovered Kuiper Belt of "ice dwarfs" or minor planets. NASA originally planned to launch the Pluto-Kuiper Express in 2004 to conduct the first reconnaissance of Pluto and its large moon Charon with low mass flyby spacecraft, using advanced technologies to serve as a pathfinder for low cost exploration of the outer Solar System. The scientific goals of the mission were to 1) characterize the global geology and geomorphology of Pluto and Charon, imaging both sides of each 2) map the surface composition and 3) characterize Pluto's neutral atmosphere, including composition, thermal structure, and aerosol particles.

Figure 1: Pluto-Kuiper Spacecraft in Orbit Around Pluto

Need for a lower cost approach

Missions to the outer Solar System are by nature complex and expensive and it soon became clear that the funding was inadequate to launch the series of missions NASA had hoped for during the next decade. Last fall, NASA Headquarters announced that - because both the Pluto-Kuiper Express Mission and the Europa Orbiter mission to follow it were now certain to cost almost twice as much as the Jet Propulsion Laboratory had first suggested - the 2004 Pluto mission would be cancelled, to ensure that there were enough funds to launch the Europa mission in 2007. Europa is the subject of great scientific interest because of the possibility that it may hold life, but the Pluto cancellation nevertheless disappointed the planetary science community. They pointed out that if the 2004 launch opportunity is missed there can be no gravity-assist flyby of Jupiter to catapult them out to Pluto and that the Europa mission, on the other hand, could tolerate a launch delay without any loss of science. As a result, NASA Headquarters began soliciting proposals for a simpler, less expensive Pluto-Kuiper Belt mission, ideally one that could be flown for under $500 million.

As the request for proposals put it: "Every aspect of the investigation must reflect a commitment to mission success while keeping total costs as low as possible. Consequently, the investigation should be designed to emphasize mission success within the specified cost and schedule constraints by incorporating sufficient cost, schedule, and design margins, reserves, and content resiliency." MSFC with partners Teledyne Brown Engineering (TBE), Los Alamos National Laboratory (LANL), and NASA Glenn Research Center (GRC) put together a team of engineers from the disciplines involved, including structural, thermal control, propulsion, and avionics, in an effort to meet this challenge. These engineers developed rough order of magnitude subsystem level design specifications, in many cases developing multiple alternative designs. The MSFC/TBE/LANL/GRC design efforts resulted in a Pluto Orbiter which far surpassed the original specification for a flyby mission. Their work was turned over to the engineering cost group, the group that is responsible for developing cost estimates of various proposals for accomplishing this mission. NASA has used parametric costing methods for about three decades. One tool that they used on this project is the NASA/Air Force Cost Model (NAFCOM96) which is an innovative tool for developing a high level estimate of aerospace program costs.

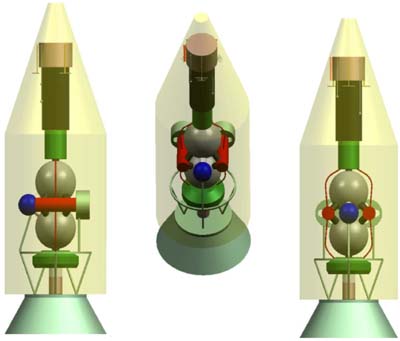

Figure 2: Three Views of Pluto-Kuiper Spacecraft in Launch Vehicle Shroud

Need to penetrate to subsystem level and below

"NAFCOM is a great tool for system level analysis," said Mahmoud Naderi, aerospace technology technical manager for MSFC. "It's designed specifically for aerospace projects and does a great job of capturing the way the government works. But it has its limitations, including the fact that it is primarily designed for use at the system level, so it doesn't capture differences in approach at the subsystem or component level very well. Also, this tool can't incorporate the effects of risk on a project, such as the possibility that a certain subsystem may end up costing considerably more than we originally estimated. For these reasons, and because we like to compare the results of multiple tools, we have begun using commercial software packages to provide complementary cost estimates. One of the commercial tools that we use most is SEER-H from Galorath Incorporated (www.galorath.com), which penetrates to the subsystem level and below, while allowing us to analyze alternatives and risk factors at any level that we choose. It has the rich feature set that you would expect from a leading commercial package, including the ability to capture virtually any technical detail you can think of and include it in the analysis."

SEER-H has approximately 40 knowledge bases for electronic elements and for mechanical. While SEER-H is primarily focused on the development process, it also includes manufacturing cost estimation capabilities for low volume production. The program is sensitive to the difference between mechanical and electrical elements and between labor and materials costs. It also bases the price of individual PCBs on their number of components rather than their weight, an approach that usually provides more realistic results. SEER-H allows the user to choose the probability level of estimates, and set different levels for each portion of the project. It also provides detailed sensitivity analysis features that make it possible to determine the impact of adjusting specific project factors. This feature, for instance, makes it possible to quickly estimate the impact on cost if a project schedule is compressed by two months. This software package reduces the learning curve by avoiding the use of less-than-obvious adjustments in order to present the estimating objective more clearly.

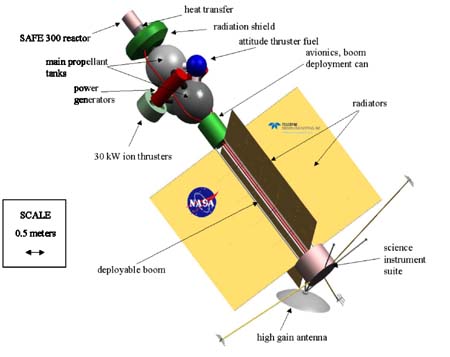

Figure 3: Pluto-Kuiper Spacecraft Fully Deployed

Generating the parametric model

Charles Hunt, industrial engineer for NASA, performed the analysis of several proposals on the new proposed Pluto-Kuiper Belt mission. "The project manager provided me with the general technical specifications and a weight statement," Hunt said. "I transposed the information into SEER parameters and began entering high level systems data into the software package. The process of compiling and entering the information and generating the initial model took only two hours. Then I had a completed cost model that I was able to take back to the program manager and other members of the engineering team for their feedback. In many cases, when they saw the output of the model, it prompted them to adjust their original specifications to make them more realistic. Engineers frequently provided me with alternatives and I was able to quickly use the parametric approach to provide near real-time feedback on development and manufacturing costs of each approach. As a result, we moved through many iterations at a rapid pace, continually improving the accuracy of the model. As detailed information is developed by the engineering team, we will capture that in the program. SEER-H will search through its database for similar assemblies and then use the experience gained from earlier programs to improve the accuracy of the model. I will stay involved with the project and continually update the model to reflect the latest thinking of the design team."

With SEER-H and other tools, Hunt is in the process of providing the project team with a realistic, well-documented budget that they can take to Congress to ask for funding. The capability of the program to quickly evaluate the cost of alternate approaches is saving considerable time during the proposal process by providing information that guides engineers toward a cost effective approach sooner than it would have otherwise been available. If the Pluto-Kuiper Belt program is approved, the SEER model will be developed to a finer level of detail and used to make subassembly and component decisions and to determine the effect of specification and scheduling changes on costs. "SEER, in combination with other tools, provides a time-efficient and accurate method for generating cost estimates," Naderi concluded.

For more information contact Galorath Incorporated, 100 N Sepulveda Blvd, Suite 1801, El Segundo, California 90245. Phone: 310-414-3222 Fax: 310-414-3220 Internet: www.galorath.com