EPOKE INC.

The Advantages of Epoke

Epoke A/S is an international company founded in 1936 and is a world leader in liquid and dry chemical spreaders. They have been awarded many prestigious engineering awards and are ISO 9001 certified.

Epoke spreaders have a full compliment of options including;

Epoke spreaders have a full compliment of options including;

From Hopper to Road

Epoke bulk spreaders are unique to any other spreader mainly due to it's conveyor / material dispensing system. Material is first thoroughly stirred in the hopper by a special spiked agitator. The agitator loosens up any lumps and prevents the problem of bridging. With this feature, material can remain in the hopper between spreading operations - thereby reducing your operating and material expenses.

Accurate Dosage

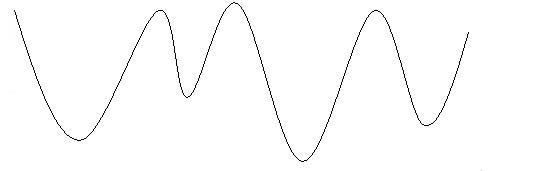

Spread rate accuracy has much to do with length of the "material exit point" of the spreader. Conventional spreaders have a material exit point (trap door) of approximately 18 inches (side to side). A six inch lump of material can cause up to a 33% loss of rate in a conventional spreader.

With Epoke material is metered from the hopper by a rotating feed roller barrel. The feed roller extends the full length of the spreader (100 inch exit point) therefore - capable of dispensing precise amounts of material. A six inch lump in this case would only cause a 6 % loss of rate.

The impact of being able to accurately dose material is significant:

- Less Risk / Lower Liability. The surface receives the intended material rate/reduced occurrence of road receiving a rate that is too low.

Spread Rate/Environmental Impact. Overall material application rates can be reduced when a consistent rate is possible.

Spread Width / Automatic Spread Rate Compensation

Displayed to the operator in a simple "grams per square metre" measurement, Epoke spreaders automatically increase the rate to compensate for increased road surface area. This provides the precise rate required for the surface area requiring treatment. Avoids the occurrence of salt being spread too thick on narrower roadways – or conversely on wider areas – too thin!

High Capacity Pre-wetting

Epoke is the leader in prewetting and anti-icing systems where in Europe prewetting has been in use for over 20 years. Numerous European Countries have conducted vast research in prewetting application rates and have concluded that a 30 % ratio (to dry material) is the most effective. This high ratio of liquid features many special advantages and abilities:

- Proven activity performance that automatically reduces material use by 23%

De-ices roads much quicker than dry materials (salt needs liquid to work) resulting in reduced liability / improved service

Reduces material bounce allowing for higher speed spreading and results in less material on non-road areas. Allows use of finer grain material for highest possible vehicle application speed (reducing traffic/spreader speed variance)

Improved cold weather performance (-13°C or 10°F)

Data Collection/GPS - If you want to improve something - measure it!

In conjunction with the EpoMaster Controller, EpoVision Software offers advanced data collection utilizing the Global Positioning System. With EpoVision (and a Windows based PC) you can see a map of each operators run complete with details such as spread width and quantity settings in that day, week, month or season. This allows operators and management the ability to:

- Discuss problem areas and plan optimal width and quantity settings along each route - so you can meet, yet not exceed, the material requirements of the road.

Keep a permanent record which can aid defense of lawsuits that claim service negligence ("your honor, on January 16th at 7:09 a.m. we spread 30 grams per meter at that intersection")

Graphical displays that can be compared to reference runs for training of operators new to that particular route

Present or future use in providing contractor performance receipts

Spreader data is downloaded from the controller via SRAM card, cell phone, or radio frequency. EpoVision is an essential tool to help reduce your de-icing material costs and a big help in managing de-icing operations.

Smart Mounting

The leg system allows the spreader to be quickly off loaded (in 5 minutes) without the use of hoist equipment (even when fully loaded). This allows your truck to be available for snow/dump operations, is easy to remove install in the spring/fall for other hauling operations. Provides you the opportunity to substantially reduce your organization's overall equipment or rental costs and can better utilize your human resources.

Other installation mounts include fixed frame, hook lift/swap body type, flat bed mount or roll off style.

The Way You Want It

Epoke designs and manufactures their OWN components - one supplier for spreader, controls, GPS/datalogging and prewetting systems. No having to deal with a mish mash of component suppliers. You own one system and deal with only one fully responsible company.

Proven Product, Proven Service

We understand the importance of your finding the right equipment and of it being backed by the right company. Some prominent clients have adopted Epoke's spreading system due to its distinct product advantage and after sales support.

Major customers now include 32 units in service for the region of Ottawa. 16 units with the Canadian Military. Most major airports are now using Epoke spreaders including Chicago, New York, Toronto Pearson and Vancouver. Recent orders include 27 units for the U.S. Air Force.

Our parts department stock a full selection of replacement parts- so down time is kept to a bare minimum. We offer full factory authorized service and warranties and are setup to provide quick response emergency service nation-wide.

For more information please call or email us.

Eagle Airfield Ltd.

10 Trent Drive

Campbellford, Ontario KOL 1L0

Canada

Phone: 705-653-0317

Fax: 705-653-4732